UAV LiDAR integration

Drone mounting solution for simple and quick deployment.

Easy multi rotor drone integration

Our UAV LiDAR Systems are drone agnostic. We provide a complete mounting solution for multi rotor drones including:

- Mechanical integration

- Electrical integration

- Dual heading GNSS

Payload

Routescene’s UAV LiDAR Systems have been designed to fly on any aerial platform that can carry a payload of between 2.0kg (4.4lbs) and 2.4kg (5.3lbs), the weight depends on the LidarPod configuration you choose. This weight includes the LidarPod, the UAV mounting kit, cables and GNSS antennas and poles.

1. Mechanical integration

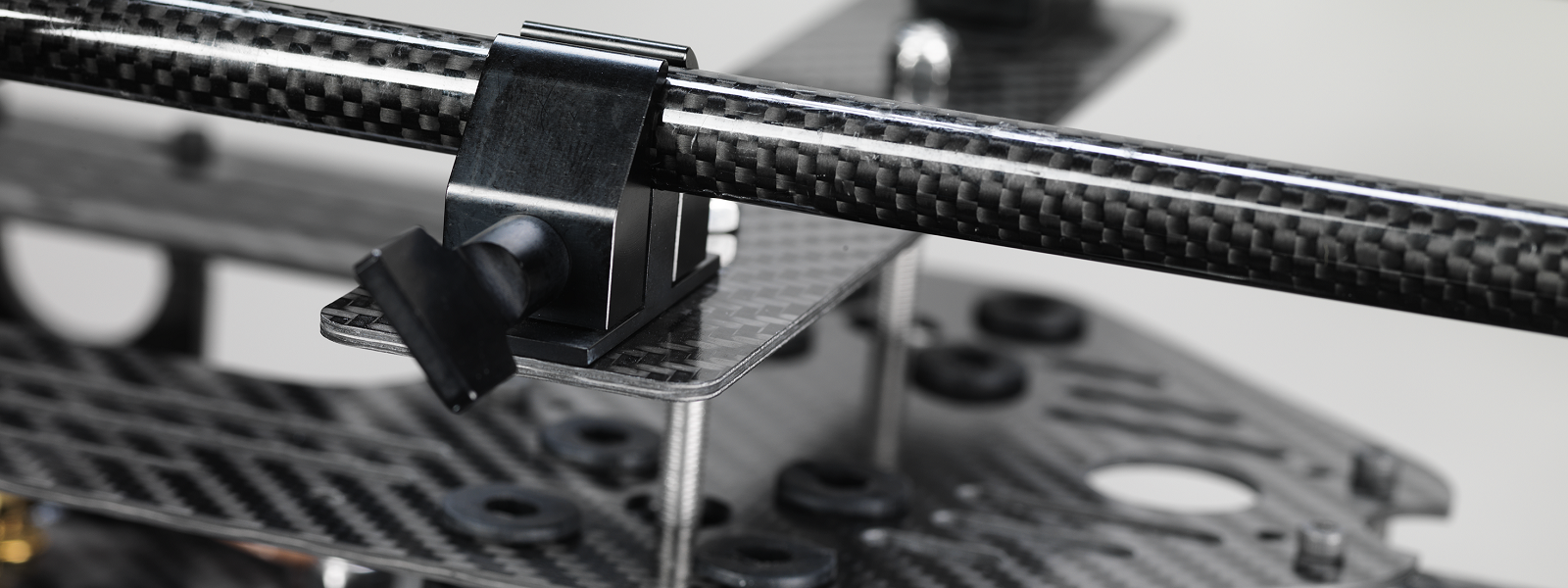

Anti-vibration mounting kit for simple integration

The LidarPod has been flown on numerous models of commercial drone and our specially designed vibration damping mounting kit allows for simple integration on any multi rotor UAV. Made from carbon fiber it is lightweight to reduce the impact on flight times. Created to reduce the transmission of vibrations from the UAV to the LidarPod, the mounting kit connects directly onto the drone and is simple to deploy.

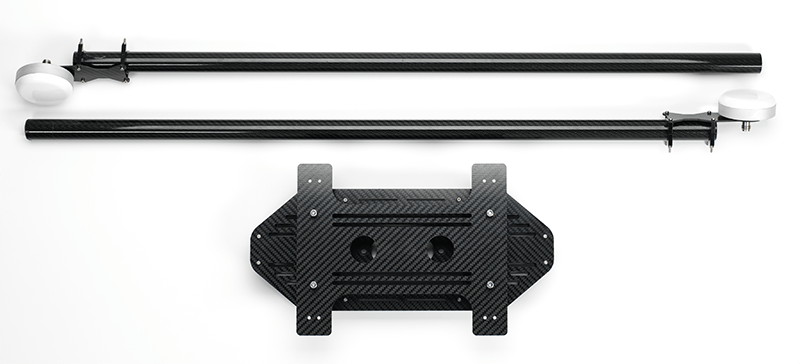

Vibration dampening mounting kit

Technical specification:

The UAV mounting kit includes an equipment plate that is compatible with 12mm diameter UAV equipment rails, which is the standard for most industrial drones.

The equipment rails are 150-155mm apart. The equipment plate can easily be modified to integrate with the mounting system on your chosen drone. The equipment plate includes quick-release clamps for easy deployment.

Mounting kit weight: 0.6 kg

2. Electrical integration

Powered directly from your drone

The LidarPod is a self contained unit and is easy and quick to deploy. It is powered from the UAV via an XT60 connector. The LidarPod power requirement is low (28W) and has a negligible effect on the endurance of the UAV.

Note: The LidarPod can be powered using a dedicated 3S battery however this also adds to the total payload weight and may prove to be the least efficient method overall.

LidarPod and UAV electrical integration

Technical specification:

The LidarPod supports a wide voltage input range (11-48VDC). This enables it to be compatible with drones that use a high voltage electrical system, this is more efficient and minimizes power losses.

3. Dual heading GNSS

What is heading?

The term “heading” describes the current direction in which the drone and payload are moving. Heading is measured in degrees (there are 360 degrees in a full circle), clockwise from either the true or magnetic North. You need to know your heading to navigate the drone.

Why do I need dual heading?

For airborne and UAV LiDAR surveys the best method to establish heading is using dual antenna GNSS. A GNSS true heading is achieved by using two antennas on the same GNSS system. This method provides not only position and velocity information but also a true heading which remains accurate even when stationary.

Advantages of dual antenna GNSS are:

- Works when stationary

- Calibration-free

- Free from magnetic disturbances

- It is the most accurate solution.

Analysis of single antenna GNSS\INS systems on the market concluded that a dual antenna system provides a heading accuracy that is up to 3 times more accurate. This heading accuracy gain ultimately ensures that the final point cloud is also more accurate.

Dual antenna systems are much more sensitive to GNSS conditions than single antenna systems. It should be operated in open sky conditions for optimal performance.

Dual heading GNSS

Technical specification:

GNSS antennas

Routescene’s UAV LiDAR Systems use two lightweight survey grade GNSS antennas which are optimized for dual frequency GNSS and Glonass signals.

They are tuned to ensure optimum RTK performance and are designed to withstand extreme conditions. The antennas are mounted on aluminum plates which act as ground planes, further enhancing performance and reducing multipath.

GNSS antenna poles

The antennas used to determine the heading are mounted on two carbon fiber poles extended in the fore and aft (left-right) direction relative to the LidarPod and drone.

Ideally the poles should be as long as possible as the greater the distance between the GNSS antennas the higher the accuracy of the heading. In practice we recommend the distance between the GNSS antennas is around 1.6m for a typical industrial UAV.

The GNSS antennas should be located within the rotor disk of the UAV’s propellers to reduce the effects of inertia and ensure that the handling characteristics of the UAV remain unchanged.